The Future Is Sustainable

At Shritija Rugs, our commitment to sustainability is woven into every aspect of our operations. We believe in creating beautiful, high-quality rugs that not only enhance your living spaces but also contribute positively to the environment and society. Our sustainability practices encompass responsible sourcing, eco-friendly manufacturing, water conservation, waste management, fair labor practices, and continuous improvement.

WATER CONSERVATION

-

1. Efficient Dyeing Techniques

Low-Water Dyeing Methods: Implement dyeing techniques that use significantly less water, such as air-dyeing or digital printing, which reduce the amount of water needed to apply colors to the fibers.

Natural Dyes: Use natural dyes that often require less water compared to synthetic dyes and can be applied in more sustainable processes.

-

2. Water Recycling Systems

Closed-Loop Systems: Install closed-loop water recycling systems that treat and reuse water within the dyeing and washing processes. This minimizes the need for fresh water and reduces wastewater discharge.

Advanced Filtration: Use advanced filtration technologies to purify and reclaim water from production processes, ensuring it can be reused multiple times without compromising quality.

-

3. Sustainable Fiber Treatment

Water-Efficient Treatments: Opt for fiber treatments that require minimal water, such as dry or mechanical methods, rather than traditional water-intensive processes.

Pre-Treated Fibers: Source pre-treated fibers that have already undergone necessary processing, reducing the water usage required during the rug manufacturing stage.

Sustainable Manufacturing Process for Rugs

we ensure that our rugs are not only beautiful and high-quality but also sustainably produced, contributing to a healthier planet and better quality of life for everyone involved.

Sourcing Raw Materials Responsibly

We prioritize the use of natural and sustainable fibers such as organic cotton, wool, jute, and bamboo. These materials are biodegradable and have a lower environmental impact compared to synthetic alternatives. By ensuring a traceable supply chain, we source our raw materials from suppliers who adhere to sustainable practices, providing transparency and accountability in every step of the process.

Energy Efficiency and Renewable Sources

To reduce our carbon footprint, we power our production facilities with renewable energy sources such as solar and wind energy. This transition to clean energy not only decreases greenhouse gas emissions but also promotes a sustainable future. We continuously seek innovative ways to enhance energy efficiency across all our operations.

Eco-Friendly Manufacturing Processes

Our manufacturing processes are designed to minimize environmental impact. We employ water-efficient dyeing techniques, such as low-water dyeing methods and the use of natural dyes, which significantly reduce water consumption. Additionally, we have implemented closed-loop water recycling systems that treat and reuse water within the dyeing and washing processes, minimizing the need for fresh water and reducing wastewater discharge.

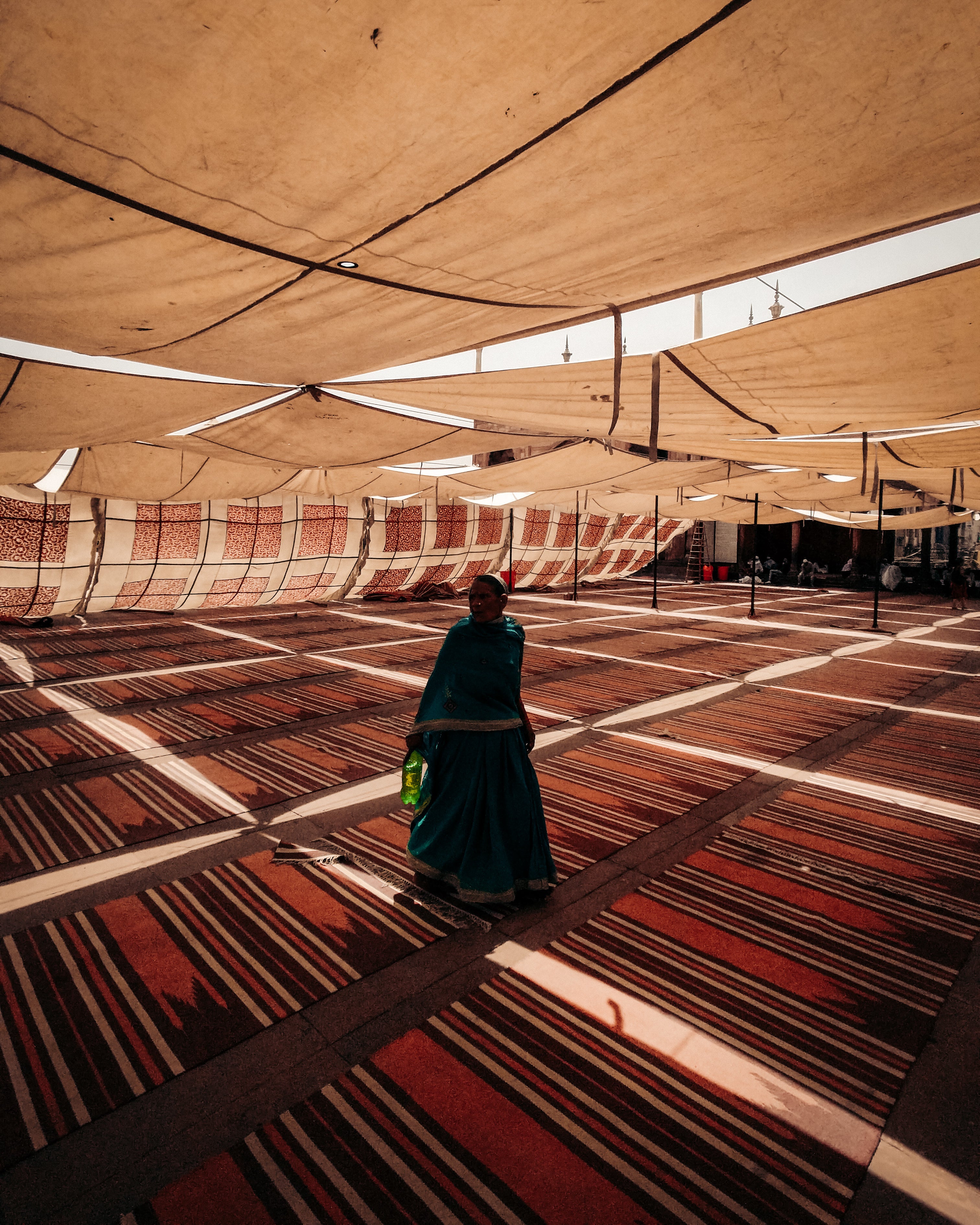

Sustainable Weaving Techniques

Our artisans employ traditional hand-weaving techniques that have been passed down through generations. This meticulous craftsmanship not only results in unique, high-quality rugs but also minimizes energy consumption, as it relies solely on human skill rather than machinery. By preserving these age-old methods, we support artisan communities and reduce our carbon footprint, contributing to a more sustainable future.

Waste Management and Recycling

We are committed to minimizing waste throughout our production process. By optimizing fabric cutting and reusing offcuts, we reduce material waste. Our recycling programs ensure that both pre-consumer and post-consumer waste are repurposed or recycled, contributing to a circular economy and reducing landfill usage.

Packaging and Shipping

In our efforts to reduce waste and environmental impact, we use minimal and recyclable packaging materials for our products. Our rugs are carefully packaged to ensure they arrive in perfect condition while minimizing the use of plastics and non-biodegradable materials. Additionally, we offer free worldwide shipping, consolidating shipments whenever possible to reduce our carbon footprint.

Fair Labor Practices

At Shritija Rugs, we value the artisans and workers who bring our designs to life. We ensure safe and healthy working conditions and provide fair wages and benefits to support their well-being and livelihoods. By promoting traditional hand-weaving techniques, we not only preserve cultural heritage but also support artisanal craftsmanship, fostering economic development in local communities.

Continuous Improvement and Innovation

Sustainability is an ongoing journey. We conduct regular audits of our manufacturing processes to identify areas for improvement and ensure adherence to sustainability standards. Investing in research and development allows us to explore new sustainable materials, technologies, and practices that further enhance the environmental performance of our products.

Customer Engagement and Transparency

We believe in engaging our customers in our sustainability journey. By providing detailed information about our materials, processes, and practices, we empower you to make informed choices. Our commitment to transparency ensures that you can trust the integrity and sustainability of every Shritija rug you bring into your home.

Shritija Rugs is dedicated to creating products that are not only aesthetically pleasing but also environmentally responsible and ethically made. Our comprehensive approach to sustainability reflects our commitment to the planet and its people. By choosing Shritija Rugs, you are supporting a brand that values quality, integrity, and the well-being of our global community.